Pure aluminum for industrial use. 99% of its composition consists of aluminum (Al).

Because of its high purity, aluminum has excellent workability, corrosion resistance (rust and oxidation resistance), and thermal and electrical conductivity, but it is not suitable for structural materials due to its low strength.

It is often used for parts and components that do not require much strength, and is a non-heat-treatable type of aluminum material that is often used without heat treatment.

No.2000 to Al-Cu series

This is an alloy with added copper (Cu), which boasts strength comparable to steel materials. It can be further strengthened by heat treatment. Well-known high-strength aluminum alloys in this series include Duralumin and Super Duralumin, which are famous for aircraft components.

These alloys offer improved strength with the addition of copper but may experience reduced corrosion resistance with higher copper content. While they excel in machinability, they can present challenges in welding. Therefore, mechanical methods or resistance spot welding are often used for assembly.

include aircraft components, screw and gear parts, molds for forming, and hydraulic components.

Commonly used materials include A2011, A2017, and A2024.

No.3000 to Al-Mn series

This alloy, with added manganese (Mn), enhances strength without compromising the workability and corrosion resistance of pure aluminum. It finds wide application in utensils, construction materials, containers, and can be further strengthened by adding magnesium.

include architectural components, roofing materials, aluminum cans, and lamp sockets.

A representative example is A3003.

No.4000 to Al-Si series

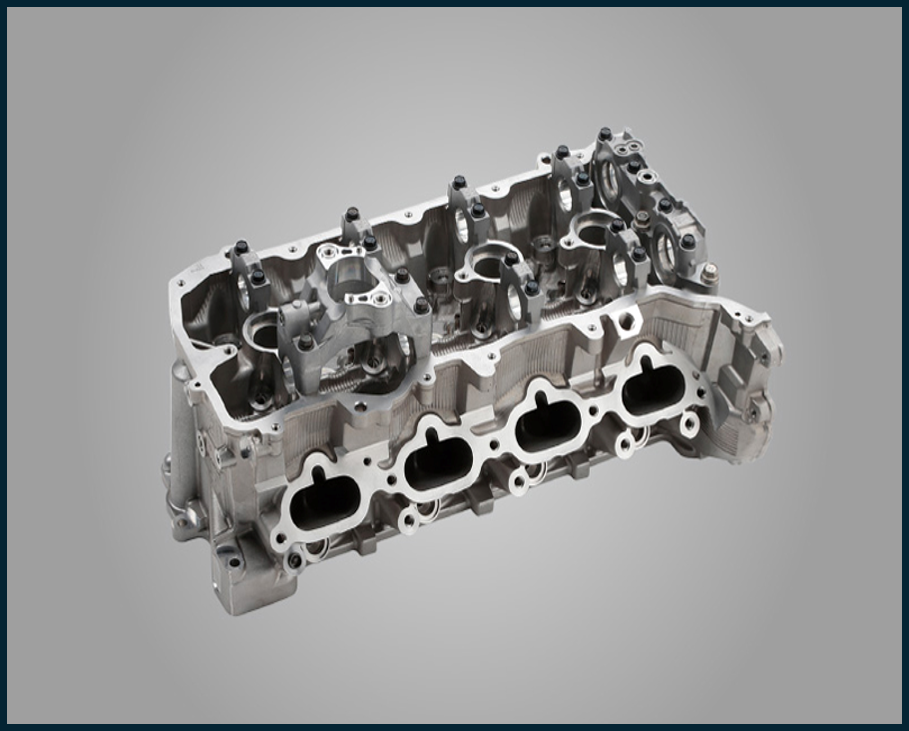

This alloy, incorporating silicon (Si), exhibits reduced thermal expansion and increased wear resistance due to silicon addition. With excellent heat resistance, it is used in forged pistons and, being lower in melting point compared to other aluminum alloys, it is also employed in welding consumables.

include pistons, cylinder heads, and welding wires.

A representative example is A4032.

No.5000 to Al-Mg series

This alloy, with added magnesium (Mg), enhances strength, corrosion resistance, and weldability. Variants with lower magnesium content are used for decorative and utensil applications, while those with higher content are utilized in structural materials for ships, vehicles, and chemical plants.

Due to the wide range of magnesium content, these alloys offer a variety of applications.

Applications include cookware, fuel tanks, architectural interior and exterior materials, and reflectors.

Commonly used materials include A5052 and A5056.

No.6000 to Al-Mg-Si series

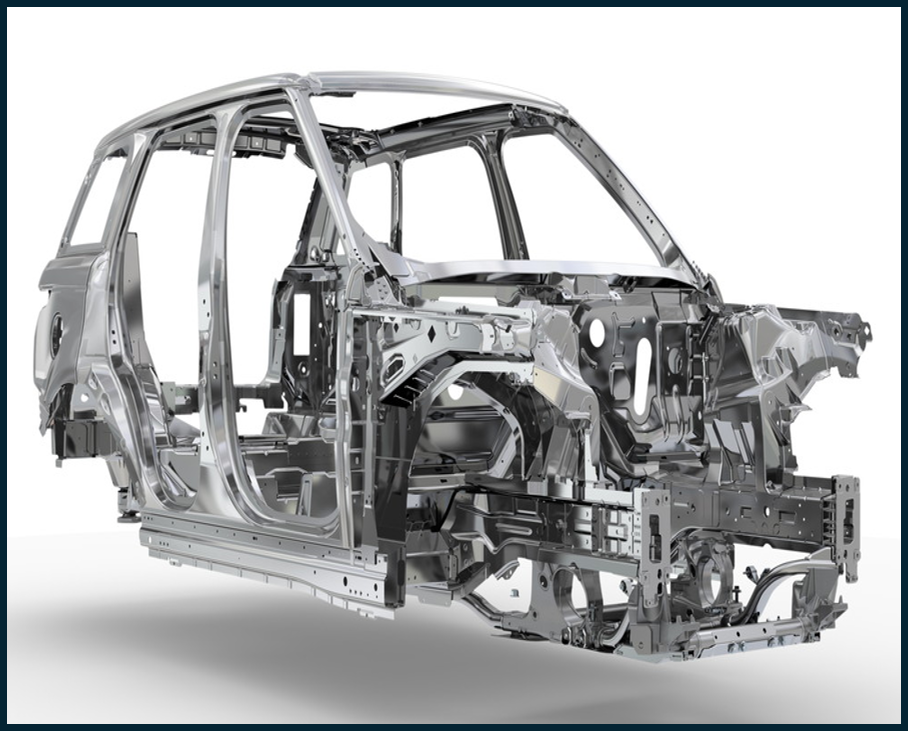

This alloy, with magnesium and silicon additions, offers superior strength and corrosion resistance, making it suitable for structural materials. It is weak in welding, and due to the high thermal conductivity characteristic of aluminum, welding can lead to strength reduction in welded and surrounding areas. Therefore, mechanical fastening methods such as bolts and nuts are often used with this material. Additionally, it excels in aging resistance and extrudability.

This alloy is utilized in applications such as transportation structural components for vehicles and ships, architectural sashes, and doors.

Commonly used materials include A6061 and A6063.

No.7000 to Al-Zn-Mg series

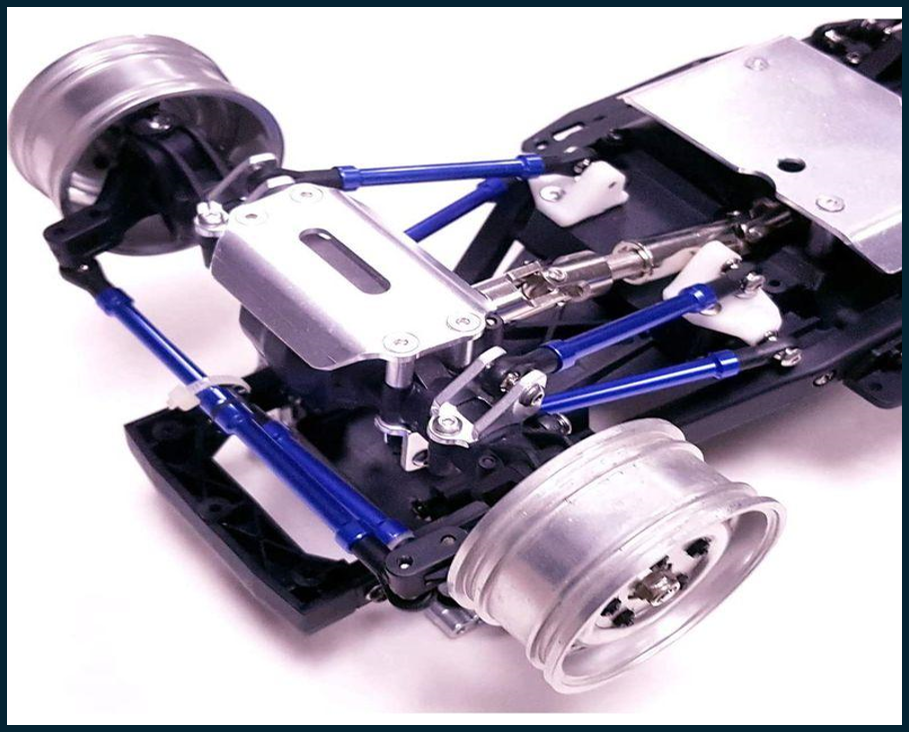

This alloy, containing zinc (Zn) and magnesium (Mg), boasts the highest strength among existing aluminum alloys when heat-treated. The 7075 alloy, known as Super Duralumin, developed in Japan, finds applications in aircraft and sports equipment.

There are two main categories: Al-Zn-Mg-Cn series and Al-Zn-Mg series alloys. While they excel in weldability, inadequate heat treatment can lead to aging deterioration, requiring careful attention.

Applications include sporting goods, mold parts, and axles.

A representative example is A7075.

No.8000 to other alloys such as lithium (Li) additives

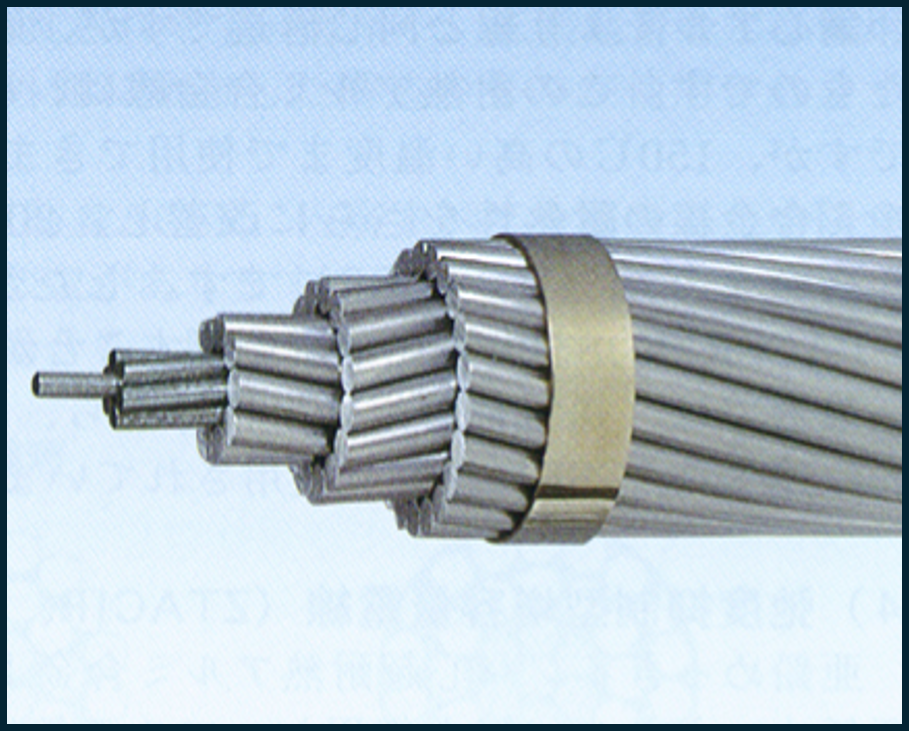

such as lithium (Li) additives: These alloys do not belong to any of the alloy series from No.1000 to 7000. Notable alloys include low-density, high-rigidity Al-Li series alloys developed for aerospace materials. Additionally, aluminum alloys for electric communication and packaging are developed by adding iron (Fe).

include food packaging materials, medical packaging, and aluminum caps.

Representative examples include A8011, A8021, A8079, and A8090.